The OPeraTIC team has been hard at work, and their efforts are delivering impressive results across the board:

- Integration for 3D motion: A high-power ultrashort pulsed laser has been successfully integrated with a non-dispersive optical fibre, facilitating robotic manipulation. This has also been combined with dynamic beam shaping to improve productivity.

- Versatile Texturing: Laser surface texturing has been demonstrated on a range of materials — including stainless steel, aluminium, and composites — using both Direct Laser Interference Patterning (DLIP) and Direct Laser Writing (DLW) techniques.

- Real-Time Monitoring: Advanced monitoring tools (both measuring beam delivery and resulting texture) have been validated for in-line use, enabling real-time control over both process parameters and product quality.

- AI-Driven Design: AI models are now supporting the design and optimisation of laser surface treatments, making development faster, smarter, and more adaptable to user needs.

- Industry 4.0 Integration: Secure communication systems and asset modelling tools have been developed to ensure seamless integration into smart manufacturing environments.

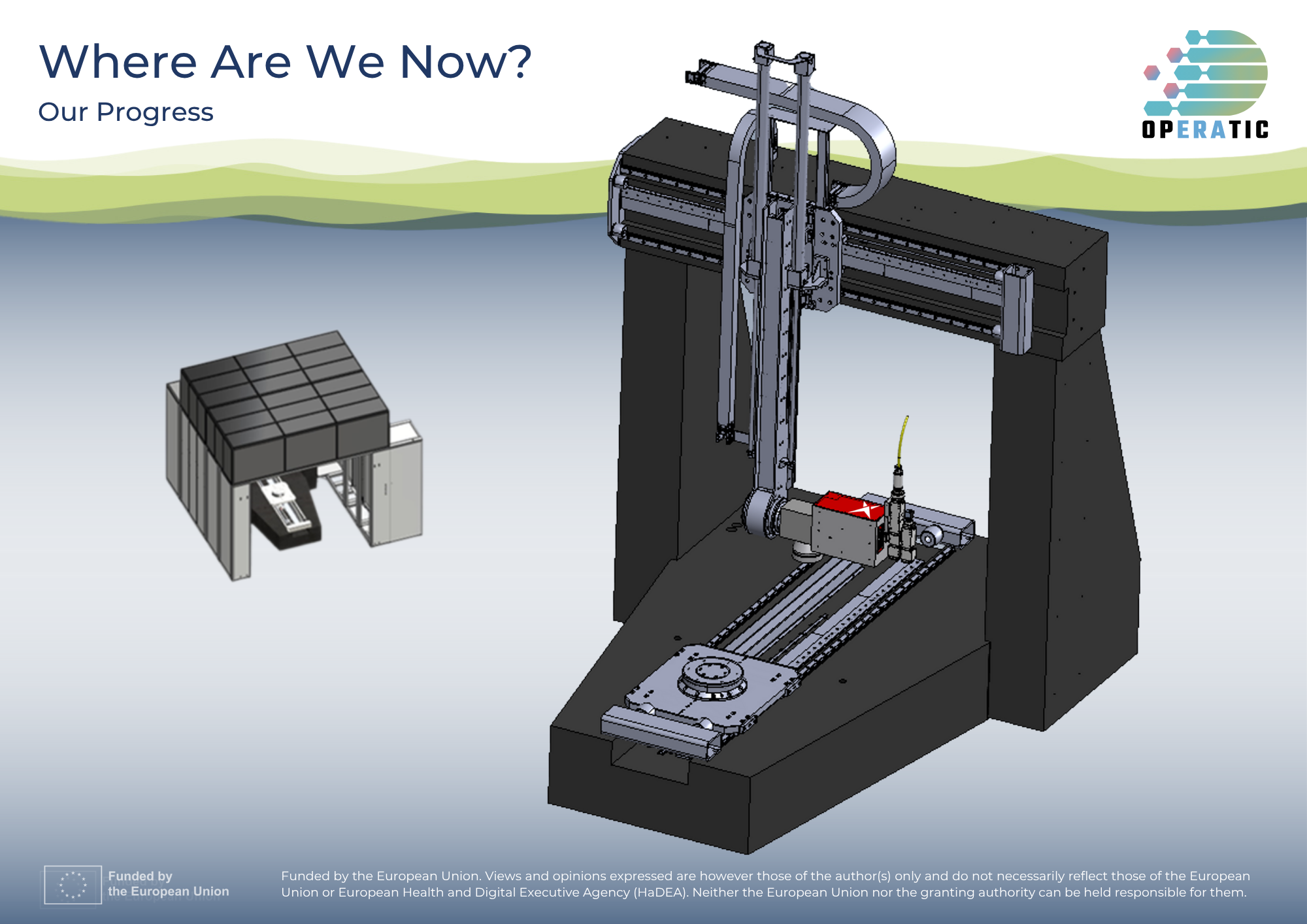

OPeraTIC continues to push the boundaries of laser-based manufacturing with a focus on energy efficiency, digitalisation, and industrial scalability. The image shows the OPeraTIC cabin including the 5-axis system for 3D laser surface processing of large-scale components (1m3 of working volume).