Let's start at the very beginning - shaping end-user applications.

OPeraTIC is at the beginning of its journey to develop a digital and mechanical platform to bring the benefits of high-powered, ultrafast lasers into large scale industrial applications. This planned system will cover all the essential aspects of laser manufacturing, including machine and digital architecture, Artificial Intelligence (AI) and adaptive processing of complex 3D parts, to enable a wide application of Ultra-Short-Pulsed Lasers (USPL) within the manufacturing sector, directly impacting the production of components used in everyday life. The four use cases included within the project have been specifically chosen to ensure this application is tested across a wide range of sectors, manufacturing processes and, ultimately, commercial relevance. The use cases, therefore, include production elements from the home appliances, aeronautics, automotive, and lighting sectors.

As OPeraTIC’s main goal is to boost the adoption of high-powered USPLs, it is essential for success that the end-users of the product are considered from the very beginning of the development cycle. It is from this approach that the research partners have begun the work of the project, seeking first and foremost to work with the end-users to define needs, expectations, and output requirements. This essential consideration will ensure that the outcomes can be defined, development processes planned, and ultimately that the correct technical modules be drawn up for the end-product, ensuring appropriate patterns, productivity and quality can be achieved for the end-users.

Use Case 1- Home Appliance Sector

Targeted Function: Hydrophobicity Re-manufacturing

Aim: to reduce water and energy consumption in dishwasher drying cycles.

Objective: Enhance the contact angles of the interior component parts.

OPeraTIC solution: use hierarchical micro-nano topographies to achieve Ultra-Short-Pulsed Lasers (USPL) micro-structuring of the injection moulding tool, transferring the texture to the actual part.

Impact: Reduction of water and energy consumption, improved drying process

, extended lifespan of product, avoid plasma coating, achieve better environmental impact, and improve the Restriction of Hazardous Substances (ROHS) compatibility.

Use Case 2- Aeronautics Sector

Targeted function: Improved adhesion/paintability

Aim: Reduce time consuming and harmful sanding process in current preparation processes.

Objective: Improve the paintability of components while improving the process yield, repeatability, flexibility, and decreasing rejection rates through use of lasers.

OPeraTIC solution: Surface texturing through customised energy distribution of high-energy USPL on the component, ensuring optimal adhesion between composite and paint, as well as avoiding pores.

Impact: Damage avoidance to Kevlar matrix and provision of a functional surface within a competitive process cycle time, high repeatability, reduction in rejection rates and increased yields, improved worker health and safety conditions.

Use Case 3- Automotive Sector

Targeted function: Improved lubrication and re-manufacturability

Aim: Reduce wear, adhesion, and defects in steel blank stamping and deep drawing.

Objective: Improve lubrication and homogeneous gripping, thus also improving formability of intricate shapes, speed of processes and reducing forming steps.

OPeraTIC solution: Utilise USPL machining of micro-reservoirs in a stamping tool.

Impact: Reduction in energy use, oil, and feedstock, extension of die lifespan, reduction in process downtime, and enabling manufacturing of complex geometrics and difficult materials, and reducing forming steps from 7 to 4.

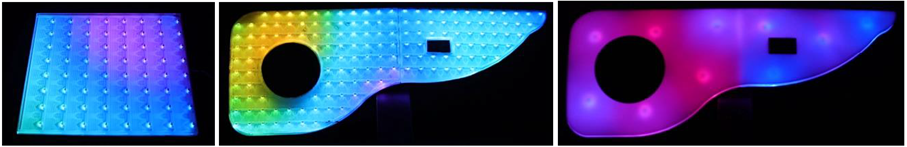

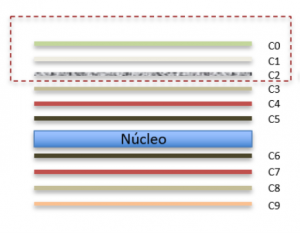

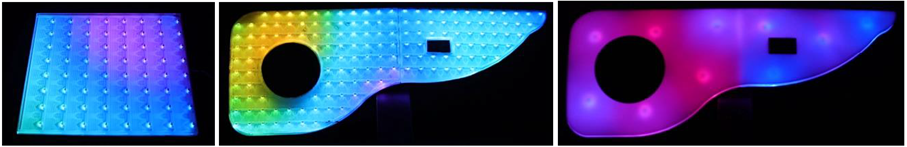

Use Case 4- Lighting / HMI Sector

Targeted function: Functional structuring of backlit panels

Aim: Reduce LED power and energy use in LED Backlit Units (BLU)

Objective: Increase visible light transmissions and lower dielectric permittivity, increasing integration capacities with BLUs and/or capacitive sensing electrodes.

OPeraTIC solution: Use direct laser selective patterning to allow mass customisation in design and function.

Impact: Meet the next wave in automotive design through creating high-quality 3D light emitting surfaces, with dynamically addressable luminance.

Paving the way for wider uptake of USPLs

In the initial 8-months of the project, the research partners have evaluated, alongside the end users, the basic structure information, material, criteria and methodology for analysing the outputs following laser treatment, and any post-treatments allowed. By setting these base-line indicators, the true impacts and benefits of USPL processing can be seen and extrapolated for additional sectors and industrial component parts. From here, the OPeraTIC partners will be able to advise and guide both policymakers and standardisation organisations as to the value that such development could achieve for industry.

It has been the initial objective of OPeraTIC to define the applications of the four end-users to enable a benchmark to be set for the research and process development to be carried out throughout the following years of the project. Each use case has now secured the required performance and quality expectations from the end-users to enable the project partners to begin planning and implementing the laser-based solutions.

Throughout the coming three years, the outcomes and impacts of this research, where possible, will be made available to the scientific community through this website as well as other open-source platforms such as OPENAIRE, ensuring that the learnings are disseminated where they can be most effective. It is the hope of the partners that such research will encourage the use of USPLs in industrial manufacturing, thereby enhancing the potential of the photonics sector to revolutionise large scale industrial production.